Balancing Inventory Levels and Service Efficiency

Inventories are materials and products waiting for processing, transport, sale or use in production and logistics systems.

Supply chain management focuses on correctly managing inventory flows within and between facilities.

The types of materials and inventories present in a supply chain can be summarized as follows:

- Raw materials or semi-finished goods awaiting processing

- Maintenance, repair and overhaul items not part of finished products

- Finished goods in warehouses awaiting sale or shipment

- Materials in transit

- Finished goods held at customer locations

- Components serving as spare parts for products

Inventory management ensures that right materials are available in the right quantity, at the right place, at the right time and at the right cost. Inventory is one of the largest cost items for many companies. Organizations that manage inventories effectively gain competitive advantage. Poor inventory management leads to losses in cash or sales.

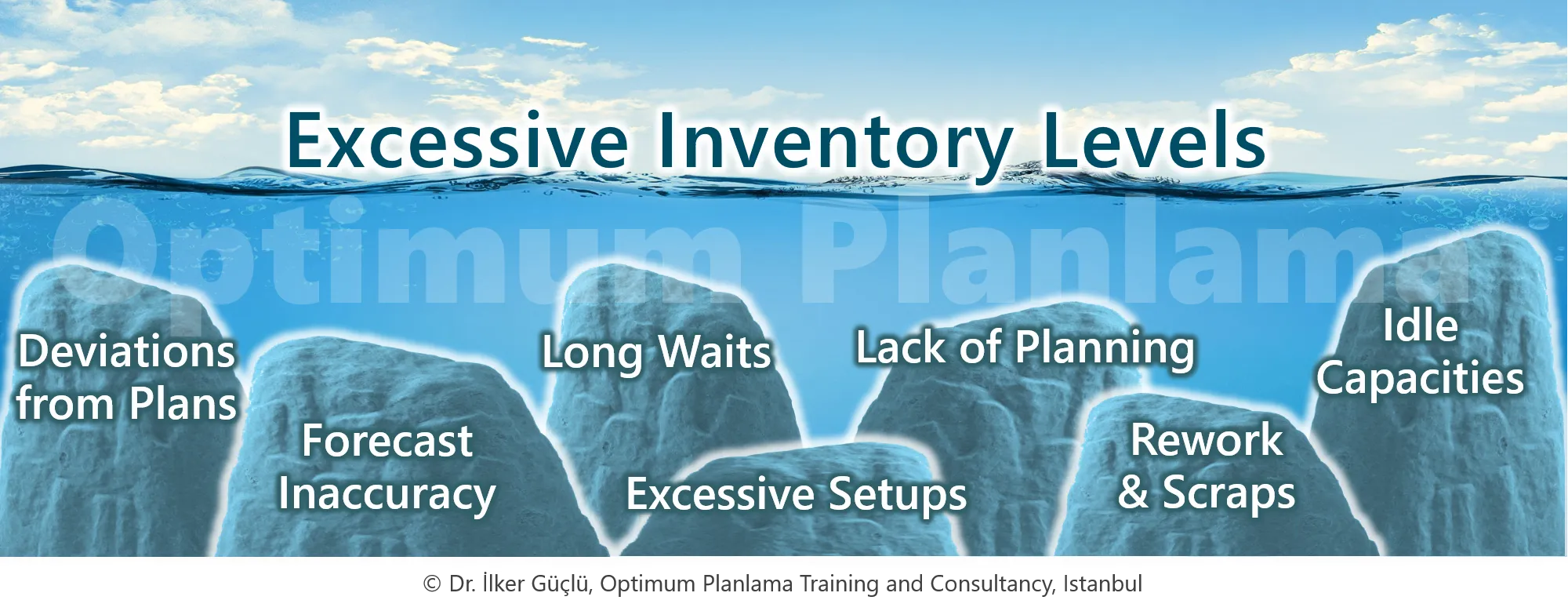

Excessive inventory can hide many supply chain and production problems...

image:

optimumplanlama.com

image:

optimumplanlama.com

What are the Main Objectives of Inventory Management?

Effective inventory management encompasses many approaches and activities aimed at improving an organization's competitiveness. The main objectives can be summarized as:

- Continuously meeting customer demand

- Ensuring material flow in production

- Avoiding costs caused by excessive inventory

- Preventing lost sales and production stoppages due to insufficient inventory

- Improving profitability through efficient use of capital

Holding inventory is necessary in supply chain management. In some cases inventory levels will exceed immediate need. The factors below may justify holding inventory above demand:

- Gaining economies of scale in purchasing and production

- Protecting against uncertainty in customer demand

- Protecting against uncertainty in supplier deliveries

- Expectations or rumors of price changes

- Balancing production needs, etc.

Companies can add many factors specific to their operations. The large number of drivers makes effective inventory management a challenging task.

What is Inventory Segmentation?

Inventory segmentation groups inventory items according to criteria so that each group's characteristics and needs are better understood. Segmentation helps make more focused and effective inventory decisions.

Typical inventory segments include:

| Inventory Segment Examples | ||

|---|---|---|

| Cycle inventory | Safety inventory | Speculative inventory |

| Idle inventory | Dead inventory | Distribution inventory |

| Maintenance, repair & overhaul inventory | Consignment inventory | Quality control inventory |

| Returns inventory | Seasonal inventory | Hedge inventory |

| Strategic inventories | Promotional inventories | Reserve inventories |

What Inventory Analysis Methods are Used?

Various analysis methods help classify items and guide planning and control processes:

| Inventory Analysis Methods | |||

|---|---|---|---|

| ABC Analysis | XYZ Analysis | VED Analysis | SDE Analysis |

| FSN Analysis | HML Analysis | SOS Analysis | etc. |

Combinations of these methods (e.g., ABC–XYZ) are commonly applied.

These tools enable prioritization, control level setting and efficient resource use. Inventory analysis methods are critical tools that help improve competitiveness.

What are the Challenges in Inventory Management?

Core challenges stem from uncertainties and variability on the customer and supplier sides, plus operational and capital cost issues. These challenges can be addressed by reliable forecasts and effective planning.

Service level measures the success in meeting demand; it is closely tied to inventory availability at the moment of need and directly affects sales. Hence it is an important competitiveness metric.

Inventory costs arise from purchasing, producing, storing inventory, opportunity costs and overheads.

Trade-offs between service level and inventory costs must be decided for each company.

The goal is to determine inventory levels that meet service level expectations while keeping total costs low.

Organizations must accurately compare the costs of holding versus not holding stock.

How to Optimize Inventory Levels?

Inventory optimization adjusts stock levels to best meet the organization's needs and objectives, seeking to minimize inventory costs while maximizing service levels. Two key decisions are when and how much to replenish. Various methods and tools support these decisions:

| Inventory Optimization Methods | ||

|---|---|---|

| Continuous Review (Q) Systems | Periodic Review (P) Systems | Economic Order Quantities (EOQ) |

| Periodic Order Quantity (POQ) | Just-In-Time (JIT) & Kanban | Safety Stock Calculations |

| ABC Analysis | XYZ Analysis | ABC–XYZ Matrix |

| Service Level Optimization | Multi-criteria Decision Making (AHP, TOPSIS etc.) | Simulation & Scenario Analysis |

| Automated Replenishment | Forecasting with Machine Learning | MRP (Material Requirements Planning) |

| Demand Forecasting Methods | Mathematical Modeling | DDMRP (Demand Driven MRP) |

There are common practices applicable to many companies. However, factors such as: sales, production and procurement strategies, product and process characteristics, supply chain operations and relationships, customer and supplier expectations, and assumptions about future actions are mostly company-specific, meaning that inventory optimization must be tailored per organization.

These factors require inventory management processes to be designed like tailor-made solutions for each company.

image:

pexels.com

image:

pexels.com

What Services Does Optimum Planning Offer in Inventory Optimization?

Optimum Planlama offers hands-on trainings and consulting services to configure inventory management and optimization processes and the related tools tailored to your organization.

We recommend starting with in-house workshops to embed the optimization mindset and align stakeholders.

Our offerings on inventory management processes and related services include the items below.

To arrange an in-house training for your organization or to join a public session, request our proposal.