From Planning to Detailed Scheduling

Detailed Scheduling (DS) is determining the start and completion times of processing, setup and transfer operations by resources in production systems.

Detailed scheduling is the planning layer where the most detailed operational planning of production is carried out and is critical for the effective and efficient management of production processes.

To learn more about production planning, click here.

Detailed scheduling aims to ensure optimal resource utilization at every stage of production processes and timely delivery.

Gantt charts are effective tools that can be used in detailed scheduling

for determining job sequences and monitoring workflows.

image:

optimumplanlama.com

image:

optimumplanlama.com

The sequence in which jobs and operations should be performed is determined based on shipping, production and material supply plans.

Flexible and adaptable detailed schedules are created taking into account various constraints and uncertainties encountered in production processes.

What Factors Should Be Considered in Detailed Scheduling?

Many factors need attention during detailed scheduling. Some examples of these factors are as follows:

- Jobs to be completed by production (work orders and/or customer orders)

- Resources required for processing and their available capacities

- Standard capacity requirements needed for processing jobs

- Promised delivery dates (due dates) or delivery time windows for jobs

- Setup times for resources and any additional setup characteristics

- Alternative resources available for processing and any additional processing characteristics

- Process plans (routes) for jobs, predecessor-successor relationships, etc.

In addition to those listed above, many more constraints and operational characteristics may exist specific to manufacturers. All these factors can affect the design and operation of manufacturers' detailed scheduling processes.

Detailed scheduling decisions are generally made through the following steps:

- Data collection: Necessary data for detailed scheduling is collected.

- Analysis: Collected data is analyzed and production processes are evaluated.

- Decision making: Detailed scheduling decisions are made based on analysis results.

- Implementation: Decisions are implemented and monitored.

- Feedback: Implementation results are evaluated and rescheduling is done if necessary.

These steps ensure systematic and efficient execution of the detailed scheduling process.

What Are the Objectives in Detailed Scheduling?

As a result of detailed scheduling, a production schedule is created showing the start and finish times of all tasks to be performed in the production environment by resources.

Considering the number and complexity of factors to be considered (available raw materials, due date constraints, capacity bottlenecks, setup requirements, etc.), being able to create a feasible schedule under all constraints can itself be considered a 'success'.

Beyond creating feasible schedules, the ultimate goal of detailed scheduling processes is to create optimal schedules that will increase resource utilizations and production quantities while reducing in-process inventory, delays, setup time losses, overtime and therefore costs.

The performance of the detailed scheduling process can be tracked with key performance indicators (KPIs).

Some indicators in this respect are listed below.

- Average completion and waiting times for work orders and orders

- On-time in-full delivery rates (OTIF, OTD) and service levels

- Capacity utilization rates for lines, machines, workers, molds, etc.

- Expediting costs in production, purchasing and shipping

- Resource capacities lost to setup times, etc.

As we emphasize for all types of planning processes, detailed scheduling also requires creating organization-specific configurations.

The production environment's scheduling needs will vary depending on production strategies, product characteristics, production's physical infrastructure, product process plans and constraints, supply chain relationships, rules and dynamics regarding due dates, and all factors affecting production.

Therefore, detailed scheduling systems need to be 'tailor-made' or 'custom-designed' for organizations.

image:

pexels.com

image:

pexels.com

Using Gantt Charts in Detailed Scheduling

While production or material plans can easily be created and tracked using tables, the most convenient tools for tracking detailed schedules are Gantt Charts.

Gantt charts visually represent the flow of jobs over time and are used for planning, monitoring and controlling production processes.

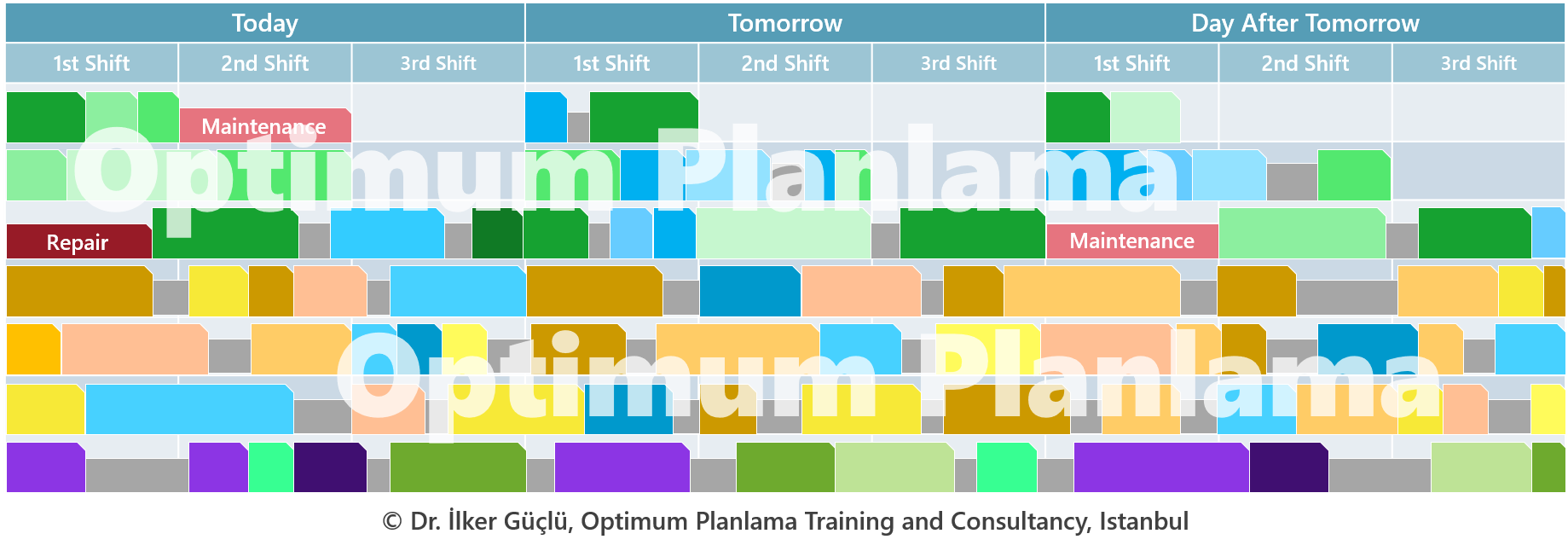

The sequence in which resources will perform jobs is a decision to be made in the detailed scheduling process. Gantt charts created according to these sequencing decisions can show the order in which resources process materials and, if necessary, the timing of maintenance, setup, etc. tasks. This view is called resource-oriented display.

image:

optimumplanlama.com

image:

optimumplanlama.com

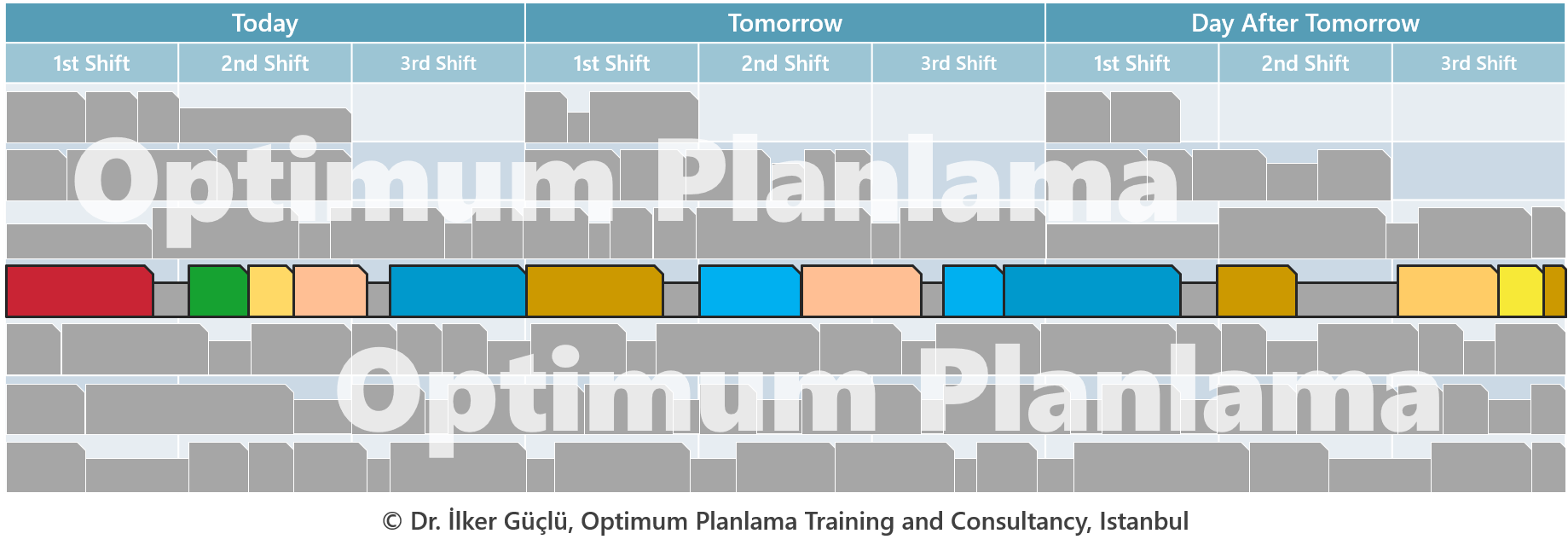

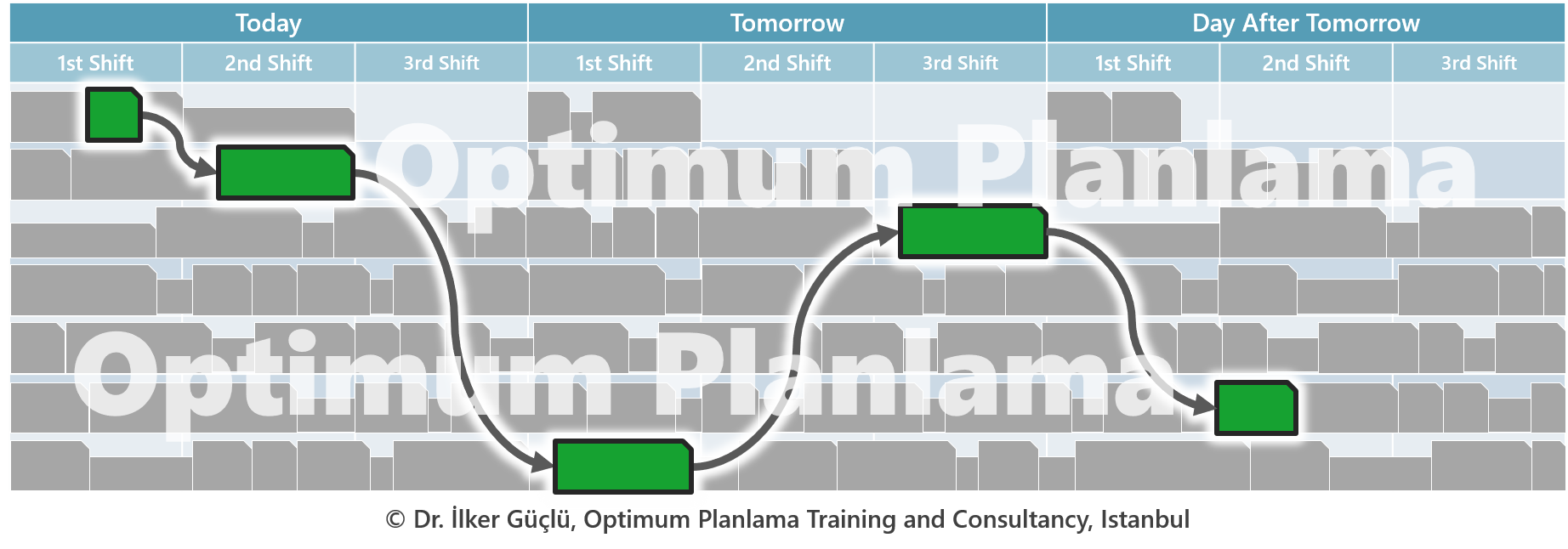

On the other hand, the resources that a specific work order or order will be processed on within the production environment and therefore the route it will follow can also be examined with Gantt charts. This view is called work order or order-oriented display.

image:

optimumplanlama.com

image:

optimumplanlama.com

Gantt charts are a useful tools in detailed scheduling processes for visually monitoring the status of jobs and resources over time, identifying bottlenecks and delays, and intervening when necessary.

What are Innovative Approaches in Detailed Scheduling?

Thanks to advances in information technologies, the application of innovative methodologies in detailed scheduling activities within production planning is becoming increasingly widespread.

Innovative approaches use various optimization techniques developed within the field of Operations Research.

In processes like detailed scheduling where numerous factors must be considered, production schedules that could be prepared manually through very long and laborious trial-and-error methods can now be created much faster, more effectively and reliably through applied innovative methodologies.

Through these techniques, scheduling decisions can be made that ensure customer satisfaction, increase organizational resource efficiency and minimize costs while achieving all this.

To learn more about optimization techniques, click here.

Organizations should first identify gaps and needs in their current production planning and detailed scheduling processes, then design how they should structure their processes.

What Does Optimum Planlama Offer for Detailed Scheduling?

Optimum Planlama provides hands-on training and consulting services for structuring of production scheduling processes and determining related tool and software needs.

We recommend in-house workshops for teams of manufacturers with multiple facilities and/or complex production processes.

Our production planning and detailed scheduling processes and related service offerings are as follows.

To arrange an in-house training for your organization or to join a public session, request our proposal.