Effective Demand Planning and Forecasting

Demand Planning encompasses all planning activities a company performs to forecast the volume and timing of demand for its products or services.

Note that, customer demand and recorded sales are not the same concepts.

Demand expresses customers’ need for a product or service; sales are the transactions that satisfy that demand.

When forecasting potential sales, using the forecasts generated by demand planning is a reliable and correct approach.

Many factors affect customers’ demand and therefore a company’s sales. These factors should be considered within demand planning activities.

What Factors Affect Demand?

To prepare a reliable demand plan, input comes from many different factors: data, information and events compiled from internal and external channels.

We can organize factors into two main groups: internal and external factors. The tables below summarize these factors.

| Internal Factors | ||

|---|---|---|

| Historical demand and sales | Pricing policy | Delivery performance |

| Quality and rumors about quality | Logistics and production costs | New product launches, delists |

| Products' life cycle phases | Sales and marketing activities | Promotions and campaigns |

| Advertising, ATL/BTL, etc. | Social media activities | Management directives, quotas, targets |

| External Factors | ||

|---|---|---|

| Existing, new and potential customers | Seasons, important days/weeks | Weather conditions, climate change, natural disasters |

| Price changes and trends | Market contractions or expansions | Economic contractions or growth |

| Competitors' products and prices | Competitors' new products | Competitors' delivery performance |

| Competitors' sales and marketing activities | Customer satisfaction and preferences | Customers' investments and actions |

| Activities of customers' competitors | Activities of customers' customers | Major projects |

| Tenders and bulk purchases | Raw material and commodity prices | Overall logistics and production costs |

| Political and cultural factors | Exchange rates | Standards |

| Regulatory changes | VAT, special consumption taxes, price indices, etc. | Pandemics |

Companies can add many more factors to the list above. The large number of potential drivers makes accurate forecasting more challenging.

Within demand planning, it is critical to identify, group and systematically monitor the elements that influence demand.

Do Demand Forecasts Affect Competitiveness?

The forecasts produced within demand planning activities are called Demand Forecasts. The activity of producing forecasts is called Forecasting.

Forecasting determines expected demand volumes and price estimates for different segments or groupings for future periods.

Organizations that do not generate forecasts are not planning their future effectively.

Forecasts are projections about how the future will unfold. Medium- and long-term corporate planning should be based on forecasts produced by demand planning.

Price changes or promotional activities intended to influence demand will also alter forecasts. When these actions are included in the planning process, the whole activity is often referred to as Demand Management.

According to Philip Kotler, "Demand management is influencing the volume, timing and mix of demand in line with corporate priorities and objectives."

Whether we call it Demand Planning or Demand Management, generating reliable forecasts through systematic processes is critical to corporate success.

Companies that can plan demand better than their competitors will be able to plan and configure all supply chain operations — procurement, production, warehousing and logistics — more effectively. They can offer more reliable lead times and delivery windows to customers and gain competitive advantages through improved costs and prices. Those advantages lead to steady growth in market share and customer base.

In fact, a well-designed demand planning system is among the prerequisites for sustainable profitability.

We observe that many companies with production or procurement problems actually fail at demand planning.

How Are Demand Forecasts Generated?

While designing demand planning processes, a systematic approach should be followed. A typical sequence can look like the steps below.

1. Define the demand planning process.

Clarify the importance of demand planning for the organization, its role in corporate planning, inputs, outputs, objectives and KPIs. Determine the departments and roles involved.

2. Identify required data sources and systems; collect the data.

Specify the drivers to be tracked, their sources and the ERP or other information systems that will be used.

3. Analyze data to choose forecasting preferences and methods.

Decide the level of aggregation for forecasts (products, subgroups, families, categories, brands) and whether to segment by location, region or customer. Determine forecasting horizons, update frequency and other process rules. Historical data (sales, shipments, orders, etc.) should be cleaned and enriched with an events history when necessary. Evaluate numerical forecasting methods (time series analysis, regression, machine learning, etc.). Consider judgmental adjustments where appropriate. Forecasting methods are detailed later in this article.

5. Evaluate and analyze forecasting performance.

Define performance indicators for forecast accuracy and monitor forecasting performance. Carefully choose error metrics (MAPE, WMAPE, BIAS, etc.). Evaluate overall process performance, gather feedback and propose improvements.

6. Integrate forecasts into corporate planning processes.

Include forecasts in operational, tactical and strategic planning processes. At these stages forecasts may be adjusted; later sections explain how forecasts are used in practice.

What Methods Are Used In Forecasting?

Forecasting methods fall into two main categories:

- Analytical methods that produce numerical forecasts based on data.

- Judgmental methods that rely mostly on managers', employees' or experts' knowledge and experience.

Examples to analytical methods are listed in the table below.

| Averaging Methods |

|

|---|---|

| Time Series Methods |

|

| Special Methods |

|

| Machine Learning Methods |

|

Which Corporate Processes Need Demand Forecasts?

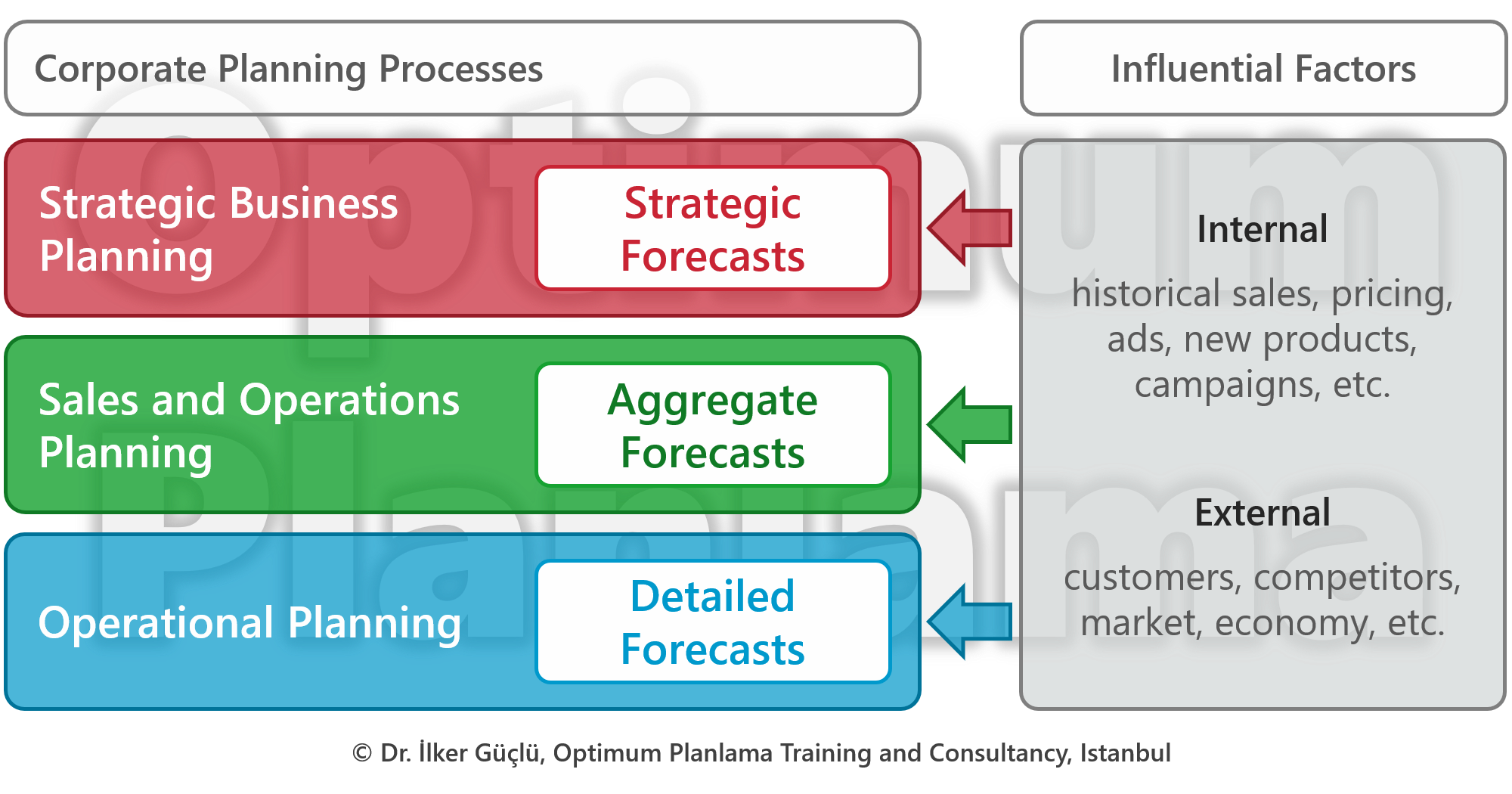

Demand planning processes should produce the forecasts required by an organization for long-, medium- and short-term planning.

Long-term forecasts are typically strategic forecasts for 2–10 years and are used in strategic business and investment planning.

Medium-term forecasts cover 12–24 month horizons and are grouped forecasts for product or service families. They are used to determine procurement, production, warehousing and logistics needs and potential bottlenecks. These forecasts are prepared within Budget Planning or, Sales and Operations Planning (S&OP) processes.

Demand Planning is one of the most critical stages of the S&OP (Sales & Operations Planning) process — also known as Integrated Business Planning (IBP).

S&OP is an integrated planning process that balances supply and demand over the medium and long term while focusing on competitiveness and profitability.

By improving cross-functional collaboration, S&OP helps organizations create plans that help them achieve corporate goals and respond faster to market dynamics.

To read our article on S&OP fundamentals, click here.

Short-term forecasts are detailed forecasts for up to 2–3 months horizon and are used for operational procurement, production, storage and logistics planning. We refer to operational execution tightly linked to S&OP as Sales and Operations Execution (S&OE).

To learn more about production planning, click here.

To learn more about material planning, click here.

To learn more about warehouse & logistics planning, click here.

Beyond internal S&OP and S&OE integration, Collaborative Planning, Forecasting and Replenishment (CPFR) among supply chain partners — sharing forecasts and plans — can drive excellence.

There are standard practices for demand planning, especially for statistical forecasting. However, sales & marketing strategies, product/brand management, production strategies, supply chain operations and relationships, the nature of customer demand, interpretation of historical data, and assumptions about future actions mean demand planning must be tailored to each organization.

These factors and priorities require demand planning systems to be designed like bespoke solutions for each company.

image: pexels.com

image: pexels.com

What Demand Planning Services Does Optimum Planning Offer?

Optimum Planning provides practical training and consulting services to configure demand planning and forecasting processes and related tools tailored to your organization.

We recommend starting with in-house workshops to embed the demand planning mindset and align stakeholders.

Our demand planning services and related offerings include the topics below.

To arrange an in-house training for your organization or to join a public session, request our proposal.