|

The total of all

systematic

planning

activities

carried out by

an organization

in order to

forecast the

amount and

timing of the

demand for its

products (or

services) with

accuracy can be

called as

Demand Planning.

Many factors

affecting demand

should be

tracked and

recorded as part

of the demand

planning

process, to be

used to generate

forecasts.

What are the

factors

affecting demand

(and sales)?

There are many

factors that

affect customer

demand and

therefore sales.

Factors (data,

knowledge,

events, etc.)

that can be

considered in

order to prepare

a successful

demand plan are

summarized

below.

|

Internal

Factors |

|

● Past

demand

and

sales

● Price

policy

● Delivery

performance

● Quality

and

perceived

quality

● Logistics

and

manufacturing

costs

● New

product

launches,

delists |

● Product

life

cycle

stage

●

Sales

and

marketing

activities

● Promotions,

campaigns

● Ads,

ATL, BTL

advertising,

etc.

● Social

media

activities

● Management

quotas

and

targets

|

|

External

Factors |

|

● Existing, new

and potential

customers

● Seasonalities,

important

days/weeks

● Weather,

global warming,

natural events

● Changes and

trends in prices

● Market growth

● Economic

growth

● Competitors'

products, prices

● Competitors'

new products

● Delivery

performances of

competitors

● Competitors'

sales & marketing

activities

● Customers'

satisfaction,

preferences

● Customers'

investments,

plans, actions

|

● Activities of

customers'

competitors

● Activities of

customers'

customers

● Large projects

● Tenders,

wholesales

● Raw material,

commodity prices

● General

logistics & manufacturing

costs

● Political,

cultural factors

● Exchange rates

● Standards

● Legal

regulations

● VAT, SCT, PPI,

CPI, etc. rates

● Epidemics,

pandemics,

natural

disasters

|

Every

organization may

choose to add

its own and

unique factors

to the above

list. The

multitude of

factors makes

forecasting

difficult,

unless the

demand planning

process is

designed

effectively.

The factors

affecting demand

should be

identified,

prioritized and

grouped based on

their

similarities or

correlations (if

necessary) and

tracked

systematically,

within the scope

of demand

planning

processes.

What is a

demand forecast?

Forecasts

created within

the scope of

demand planning

activities are

called Demand

Forecasts.

Demand forecasts

include demand

quantities and

price

projections for

various levels

or groupings of

customers and/or

products for

future time

periods.

Forecasts are an

organization's

predictions

about how the

future will be

shaped.

Organizations

that do not

forecast, will

not able to

effectively plan

for their

future. All

short-, medium- and long-term

planning

activities,

should be based

on corresponding

forecasts and

demand plans.

For this reason,

the creation of

demand forecasts

with accurate

and reliable

systematics is

critical for a

successful

business.

Price changes or

promotional

activities

influencing or

shaping the

demand may alter

the

organization's

forecasts. An

organization

that includes

such activities

to its demand

planning

activites, may

call the whole

process as

Demand

Management.

"Demand

management is

influencing

the

level, timing,

and composition

of demand

to accomplish a

companys

business

objectives and

goals."

Philip Kotler

What are the

competitive

advantages of

planning demand?

Organization

that plans its

demand better

than competition

will be able to

more effectively

organize its

supply chain

operations

(especially

manufacturing

and purchasing),

offer their

customers sooner

and more

reliable due

dates, meet or

exceed committed

service levels,

expand market

share, product

and customer

portfolio due to

their pricing

and cost

advantages, and

increase overall

competitiveness.

In this context,

the demand

planning process

can be

considered among

critical

prerequisites of

an

organization's

sustainable

profitability

goals.

Majority of

companies facing

problems

in

production or

material

planning,

actually have

problems in

planning their

demand.

How to

forecast demand,

how to generate

forecasts?

A systematic

approach should

be followed when

designing demand

planning

processes within

an organization.

The process may

require

customizations

specific to the

organization's

needs.

In general, the

following

roadmap may be

implemented.

1. Defining the

process and its

objectives

The importance

of the demand

planning and

sales

forecasting

process for the

organization,

its place in

supply chain

planning,

inputs, outputs,

objectives and

performance

indicators are

determined.

2. Determining

forecasting

levels and units

Organizations

may choose to

forecast at

different

product levels

such as SKUs,

product groups,

families,

categories,

brands, etc.

Groupings may

also be formed

based on

locations,

regions,

customers,

customer

segments, etc.

3. Deciding

temporal process

parameters

Temporal

decisions, such

as how to choose

forecasts

horizons and

periods within

this horizon,

how often to

update

forecasts, play

an important

role in

structuring the

demand planning

process.

It is

important to

decide when NOT

to forecast

and what NOT

to forecast

4. Collecting

and preparing

data

Collecting

demand or sales

data of past

periods,

cleansing these

data,

determining the

influential

factors in the

past, and

enriching the

data with

historical

events are done.

Therefore, data

and information

inputs for

generating

demand forecasts

become ready to

use.

5.

Analyzing

data and

choosing

forecasting

method

Visualization of

data as graphs

aids the

forecast

analysis and

selecting the

appropriate

methods.

Statistical or

judgmental

methods are used

to generate

forecasts. These

methods should

be appropriately

integrated into

the process, and

the performance

of chosen

methods should

be monitored.

6. Incorporating

forecasts into

organizational

planning

processes

Demand Planning

(DP) is subject

to planning

activities

designed within

the scope of

processes such

as Budgeting,

Sales and

Operations

Planning

(S&OP/IBP),

Supply Chain

Collaboration

(CPFR),

Strategic

Business and

Investment

Planning, etc.

Adjustments on

demand forecasts

are also likely

at these stages.

7. Improving

demand planning

and forecasting

process

The overall

performance of

the process is

evaluated,

suggestions and

feedback are

collected and

process

improvements are

done, when

necessary.

What are demand

forecasting

methods?

Demand forecasting

methods are grouped into

two main groups:

1.

Judgmental

methods are formed

based on the knowledge

and experience of

managers, employees and

experts.

2.

Statistical

methods create

forecasts based on

statistical methods and

numerical calculations.

Some examples to

statistical methods are

listed below.

|

Statistical

Forecasting

Methods |

|

Averaging

Methods

●

Simple

Averages

●

Simple

Moving

Averages

●

Weighted

Moving

Averages

Smoothing

Methods

● Exponential

Smoothing

(ES)

● Holt's

Method

(double

ES)

● Adaptive

Exponential

Smoothing

(adaptive

ES)

● Winter's

Additive

Method

(additive

triple

ES)

● Winter's

Multiplicative

Method

(multiplicative

triple

ES)

|

Regression

Methods

● Simple

Regression

● Multiple

Regression

Others

●

Moving Medians

●

Seasonal

Indices

●

Decomposition

Analysis

●

ARIMA, ARIMAX

●

Bass

Method

●

Croston

Method

|

Company

X

does that, let's do the same...

Is demand planning same for every organization?

There are some basic methods in demand planning that are applicble to every organization. Particularly, standard spreadsheet software can be used to generate basic statistical forecasts.

However, issues and concerns like sales and marketing strategies, management of products or brands, manufacturing strategies, supply chain operations and relations, nature and patterns of customer demand, interpretation of past data, modeling of future actions and assumptions are not the same for every organization. Therefore such issues and concerns need to be considered from an organization-based, specific perspective.

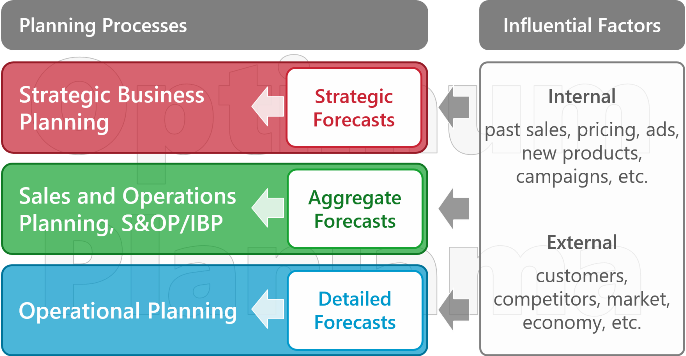

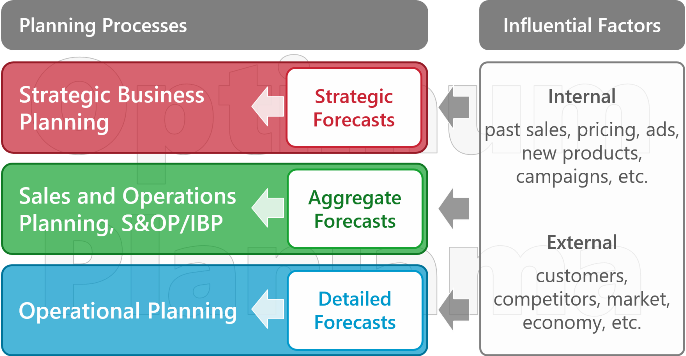

In order to to plan for long-, medium- and short-term demands, organizations generate long-, medium- and short-term forecasts. These forecasts and plans are later used in capacity, manufacturing, purchasing, etc. planning processes.

Due to aforementioned concerns and reasons and may be many more, demand planning process systematics should be custom- or tailor-made for the organization.

Optimum Planlama

provides consultancy

services on designing

and reengineering

organizational Demand

Planning processes, as

well as supporting

tools.

|

|

|

|

|

|

|

|

|

Red Bull Türkiye

S&OP/DP Project, 2022 |

Makbul

S&OP Project, 2021 |

NIVEA Beiersdorf

S&OP/DP Project, 2019 |

SİKA Türkiye

S&OP Project, 2018 |

ÇİLEK

S&OP Project, 2017 |

Contact us for more information on our consulting services regarding design and implementation of Demand Planning processes and related tools.

What

are the long-,

medium- and

short-term

forecasts?

Organizations

should have the

capacilities to

generate

forecasts at

different

periods,

horizons and

details within

their demand

planning

processes.

Long-term

forecasts are

strategic with a

2 to 10 year

horizon, usually

generated in

terms of total

sales

quantities, and

are used in

strategic

business and

investment

planning

decisions.

Medium-term

forecasts are

generated for

groups of

products (or

services) over

12 to 24 months

planning

horizons. These

forecasts are

used in

determining

aggregate sales

quantities and

revenue

projections and,

in turn possible

bottlenecks in

operations

(purchasing,

manufacturing,

warehousing,

logistics, etc.)

and financials

cash flows.

Demand plans and

forecasts at

this tactical

level are

generated within

the context of

Budgeting

and/or Sales

and Operations

Planning

(S&OP/IBP)

processes.

Short-term

forecasts are

detailed

forecasts

produced

generated in

terms of end- or

semi-finished

products to be

sold in a 3 to 6

months horizon.

They are used to

determine

operational

plans related to

purchasing,

production,

warehousing,

allocation or

transportation.

In addition to

values added by

the Sales and

Operations

Planning process

inside the

organization,

processes such

as

Collaborative

Forecasting,

Planning and

Replenishment

(CPFR) lead

the way to

supply chain

excellence,

through sharing

forecasts and

information

among supply

chain members.

|

|

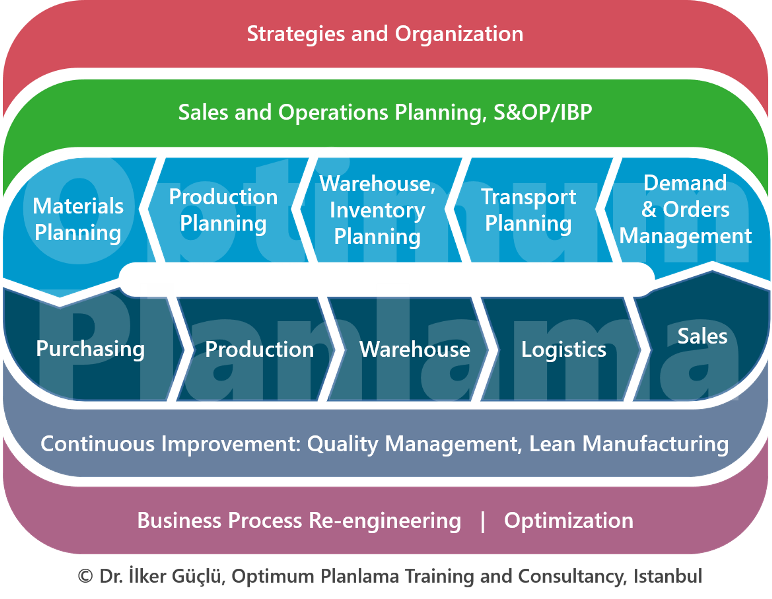

Where is demand

planning within

enterprise

resource

planning?

Enterprise

resource

planning (ERP)

can be defined

as the

management of

main business

processes in an

integrated and

coordinated

manner within an

organization.

Main business

processes, in

this respect,

can be listed as

sales,

manufacturing,

supply chain,

purchasing,

finance, HR,

etc.

Demand planning

holds a critical

position within

the scope of

supply chain

management.

Demand planning

is directly

related to

planning of

logistics,

manufacturing

and purchasing,

as well as

finance.

Organizations striving for

excellence in

their supply

chains, and

therefore in

demand planning,

need certain

functional

planning

processes in

place. These

processes are

outlined below.

In this context,

Demand Planning

lies within

Demand

Management.

Organizations

need to identify

the deficiencies

and requirements

of their current

demand

forecasting and

planning

processes, and

then improve or

re-engineer

them.

Optimum

Planlama

offers

professional

training and

consultancy

services for

organizations to

excel their

supply chain

performance.

Dr. İlker Güçlü

|

Founder,

Optimum Planlama

|

Click

for resume

This

article

is to

provide

a

general

information.

The

aforementioned

may not

apply to

all

organizations.

Optimum Planlama training programs focused on

'Demand Planning' business processes are,

|

Demand Planning and

Sales Forecasting

training

program

(V4.0EN)

|

|

|

|

Training

Goals

Forecasting customer

demand for products (or

services) has profound

effects on effectiveness

of critical business

processes, customer

satisfaction and

revenue. Generating

reliable sales forecasts

requires effective

demand planning and

forecasting procedures.

The main goals of this

program are providing

necessary knowledge on

advanced concepts of

demand planning

processes and basic

practical skills on

implementing numerical

forecasting techniques.

Verbal presentation, all

visuals and printed

material are in English.

Click for

details. |

Target Audience

Demand

Professionals

Sales

Professionals

Demand/Sales

Managers

Demand/Sales

Planners

Sales Operations

Account Managers

Marketing

Executives

Planning

Professionals

Budgeting

Responsibles

Logistics

Professionals

Supply Chain

Planners

Product Managers

Customer

Relations

|

Training

Modules

|

Day

1:

Forecasting Mechanics,

Basic Methods and

Accuracy |

Day 2:

Advanced Methods

and Process Improvement

|

|

What are the Factors

Affecting Sales and/or

Demand?

Who Generates and Uses

Forecasts?

Process Mechanics:

Horizons, Periods and

Frequency

Forecast Pyramid, Group

and Detail Forecasts

-DFUs

How to Formalize the

Forecasting Process?

Long, Medium, Close-Term

Planning Processes

In-Class Exercises

Forecasting Stationary,

Trending and Seasonal

Demands

Sales and Operations

Planning, S&OP/IBP

Process

Product, Demand and

Supply Planning in S&OP

Budget Gap Analysis,

Demand Prioritization

Supply Chain

Collaboration, CPFR

Forecast Accuracy, Basic

Indicators

In-Class Exercises

|

Quality

of Data,

Data

Cleansing

Moving

Averages,

Medians,

Weighting

Modeling

Nonlinear

Trends

Decomposition

of

Trends

with

Seasonality

Multiple

Regression,

ARIMA

Models

Exponential

Smoothing,

Holt-Winters,

Pegel

Classification

In-Class

Exercises

Lost

Sales,

Events

History,

Enriching

Data

Assumption

Management,

Top-Down,

Bottom-Up,

Middle-Out

Product

Entries/Exits,

New

Products,

Life

Cycles

Intermittent

Leads,

Promotions

Determining

Safety

Stock

Levels

Forecast

Accuracy,

Advanced

Indicators

In-Class

Exercises

|

Excellence

in your supply

chain

performance,

▲

TOP OF PAGE |