How Sales and Operations Planning Aligns Business Goals

Sales & Operations Planning (S&OP) is also referred to as Integrated Business Planning (IBP).

S&OP/IBP is the process that systematically integrates plans from different departments across an organization.

Sales, marketing, production, planning, procurement, logistics, HR and finance all play critical roles in an organization's success. Gaps in communication or coordination between these functions can hinder achieving business objectives.

S&OP creates aligned plans that improve cross-functional collaboration and enable the organization to respond to market dynamics faster and more effectively.

We start with a concise definition of S&OP and then go into further details.

S&OP is an integrated planning process,

that balances forecasted demand and available

supply,

within medium-to-long term planning horizons,

with a focus on competitiveness and profitability.

From that definition, the core characteristics of the S&OP process can be summarized as follows.

S&OP uses a rolling horizon of 12–24 months and is revisited on a monthly cadence.

Demand forecasts are prepared based on factors such as the economy, competition, seasonality, pricing and inflation.

Required inventory, production and procurement needs and bottlenecks are identified and alternative scenarios are analyzed to meet demand.

Stakeholders agree on a plan that balances demand and supply in line with corporate priorities.

Systematic preparations and planning activities are carried out, and decision-making meetings are held within the monthly cycle.

Enables continuous monitoring and improvement of corporate performance.

Creates the environment and capabilities for making strategic decisions or revising existing ones.

How Does S&OP Improve an Organization's Competitiveness?

There are many factors that can disrupt the balance between demand and supply. Examples include:

- Economic conditions, inflation, purchasing power

- Competitor actions, impacts, marketing activities

- Customer expectations, trends, social media influences

- Sales and marketing activities, campaigns and promotions

- New products and interactions between products

- Production costs, minimum wage changes, energy costs

- Procurement difficulties, quotas, tariffs, raw material prices

- Transport and storage costs, congestion, etc.

S&OP helps organizations detect changes, trends, opportunities and threats, design plans to meet demand at minimum cost, and take actions by monitoring key performance indicators. In this way, S&OP boosts organizational competitiveness.

S&OP is about timely detection of market dynamics, establishing the supply capability to meet demand, and achieving these goals with maximum profitability.

What Does the S&OP Cycle Look Like?

S&OP is a tactical planning cycle repeated monthly. It is important to distinguish tactical S&OP planning from operational planning.

Operational planning typically covers a short horizon (weekly or daily), usually not exceeding the next 2–3 months.

Organizations must perform operational planning to keep the smooth flow of daily activities, fulfill orders, prepare semi- finished and finished goods, secure raw material supply, and so on. Operational planning typically includes order management, production planning, capacity planning, material requirements planning and detailed scheduling.

Many organizations refer to their operational planning activities as S&OP, but true S&OP extends beyond day-to-day operational planning.

Properly designed S&OP consists of tactical planning activities for a mid-to-long horizon, typically 12–24 months.

Therefore, the S&OP process should be structured to make decisions about planning issues that extend beyond operational planning.

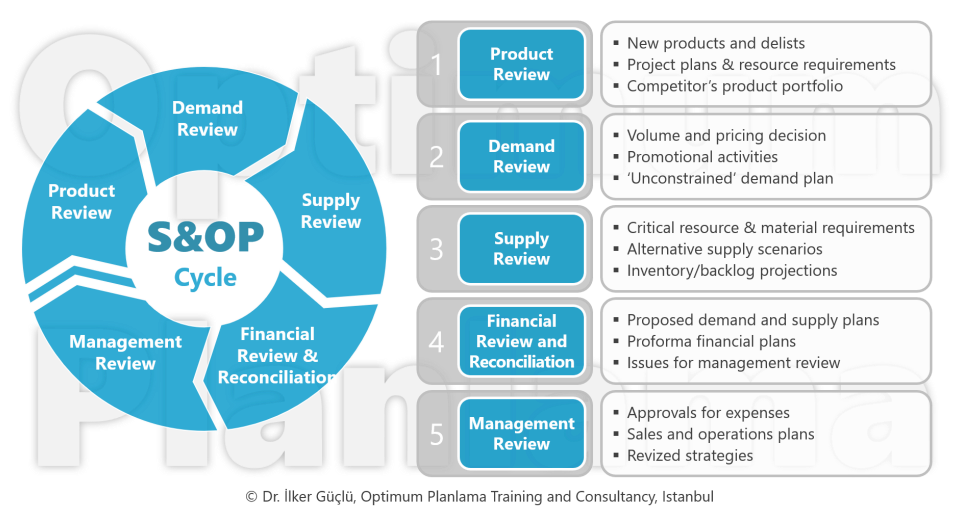

Kurumdan kuruma uygulamada farklılıklar olsa da genel hatlarıyla aşağıdaki aşamalar takip edilir:

- Step: Product Review

- Step: Demand Review

- Step: Supply Review

- Step: Financial Review & Reconciliation

- Step: Executive Review

Each step involves responsibilities for managers and staff from multiple departments and at different hierarchical levels.

The overall flow of the monthly S&OP cycle is summarized in the graphic.

Below we briefly summarize the activities in each step. Each item has significant depth and may require substantial effort.

1. Product Review

Product review ensures that project and portfolio plans are integrated into the corporate S&OP.

- Product portfolio management

- Product lifecycle management

- R&D and engineering project planning

- New product launch planning

- Corporate projects planning, etc.

2. Demand Review

Demand review integrates all market and demand forecasts into corporate S&OP.

- Demand planning and forecasting

- Pricing projections

- Campaign and promotion planning

- Marketing and sales activity planning

- Tracking and projecting competitor activities

- Forecast performance tracking, etc.

3. Supply Review

Supply review integrates procurement, production, warehousing and transportation plans into corporate S&OP.

- Critical raw material procurement planning

- Identifying supplier and production bottlenecks

- Planning storage and transport capacities

- Analysis of alternative sourcing scenarios

- Inventory projections and analysis

- Projection of supply operations costs

- Monitoring operational performance, etc.

However, they may not be executed with the scope and integration required for a mature S&OP cycle.

4. Financial Review & Reconciliation

Financial review and reconciliation integrates product, demand and supply plans with the financial plan and creates cross-functional agreement.

- Updating economic and financial forecasts

- Budget gap analysis and action planning

- Securing cross-functional alignment

- Preparing recommendations for Executive Review

- Identifying items requiring approval, etc.

5. Executive Review

The executive review evaluates the plans across functions, resolves gaps and misalignments (if any), and approves the final sales and operation plan.

- Review and approval of proposed plans

- Review of strategic objectives

- Review of financial targets

- Review of corporate performance

- Finalization of the sales and operations plan

Considering the scope of the activities carried out and the impact of the decisions made,

S&OP is the modern way to manage a company in the most competitive manner.

The way S&OP should be implemented depends on a company's production strategy, product characteristics, production environment, supply chain relationships, customer demand patterns and all other factors that influence competitiveness in the market.

The stages, sequence, roles and responsibilities, analysis methods and supporting tools vary by company. How the process should be designed and operated for a specific organization must be addressed in the conceptual design phase.

What S&OP Services Does Optimum Planlama Offer?

Optimum Planlama offers hands-on training and consulting services to configure S&OP processes and supporting tools tailored to your organization.

We recommend an organization-specific workshop as a first step to develop the S&OP mindset and align cross-functional stakeholders.

Our S&OP services and related offerings include the items below.

To arrange an in-house training for your organization or to join a public session, request our proposal.