Better Planning of Production Processes

Production (or Manufacturing) planning is the organization of manufacturing activities so that customer demands and orders are met while utilizing resources such as machines, equipment and labor in line with the organization's performance objectives.

Production planning is a critical business process for the success of manufacturing organizations.

Producers need a production planning process that responds to both customer expectations and their corporate goals.

Many factors affect how production is planned. The presence of numerous elements such as customer orders, current stocks, material requirements, resource capacities and costs makes accurate and efficient production planning challenging.

Production planning aims to balance demand and supply resources with competitive, profit-oriented decisions.

image:

Antoniusaw,

CC BY-SA 4.0, via Wikimedia Commons

image:

Antoniusaw,

CC BY-SA 4.0, via Wikimedia Commons

To design production planning processes properly, it's important to clearly define how production planning relates to other planning processes.

Considering the horizons, scopes and impacts of decisions, grouping production planning activities into hierarchical levels is useful.

Production planning decisions can generally be examined at three levels:

- Strategic decisions: Set long-term goals and corporate strategies.

- Tactical decisions: Make medium-term plans and allocate resources.

- Operational decisions: Manage weekly and daily production planning and scheduling processes.

These levels determine the scope and depth of production planning. Decisions at each level constrain and direct lower-level decisions.

Addressing production planning decisions at these levels enables more effective and efficient management of production processes.

Each hierarchical level can be further subdivided. For example, we split the operational level into two sublevels in the table below. Note that organizations may have additional levels and decisions specific to their context.

| Long-Term 'Strategic' Decisions |

In Strategic Business and Investment Planning,

|

|---|---|

| Medium-Term 'Tactical' Decisions |

Within Sales & Operations Planning (S&OP/IBP) and Budgeting,

To learn more on S&OP processes,

click here.

|

| Short-Term 'Operational' Decisions |

In Production Planning and Order Management,

In Materials and Capacity Planning,

To learn more on material planning,

click here.

|

| Very Short-Term, 'Real-Time' Operational Decisions |

In Operational Detailed Scheduling,

To learn more on detailed scheduling,

click here.

|

Abbreviations (in order of appearance): S&OP: Sales and Operations Planning, IBP: Integrated Business Planning, CPFR: Collaborative Planning, Forecasting and Replenishment, MPS: Master Production Scheduling, RCCP: Rough-Cut Capacity Planning, ATP: Available-To-Promise, CTP: Capable-To-Promise, MRP: Material Requirements Planning, CRP: Capacity Requirements Planning, TOC: Theory of Constraints

Production planning decisions are generally made through following steps:

- Data collection: Gather necessary data for production planning.

- Analysis: Analyze collected data to assess production processes.

- Decision making: Make production planning decisions based on analysis results.

- Execution: Implement and monitor the decisions taken.

- Feedback: Evaluate results and re-plan if necessary.

These steps enable the systematic and efficient execution of the production planning process.

What are the Objectives in Production Planning?

There are common practices and factors that must be considered in production planning.

For make-to-order production, meeting delivery dates and for make-to-stock production, avoiding stockouts are core objectives that ensure customer satisfaction and service levels.

On the other hand, costs arising from purchasing, production, storage and logistics must be minimized. Therefore, production planning decisions should minimize these costs while meeting demand. Related functional processes must also be configured accordingly.

Planning production better, can and will reduce purchasing, production, inventory and logistics costs.

As with other planning processes, production planning requires organization-specific custom design.

An organization's planning setup depends on its production strategies, product characteristics, physical infrastructure, supply chain relationships, demand dynamics and other factors related to competition.

The stages of production and material planning, tasks and responsibilities, analysis methods and supporting tools will vary between organizations. The conceptual design should address how the process must be structured and operated in each organization.

The fundamental approach in production planning is to organize planning activities by horizons (long, medium, short), by product groups, products, semi-finished items or operations, and by priorities and assumptions.

Therefore, production planning systems typically need to be tailored to the organization.

image:

pexels.com

image:

pexels.com

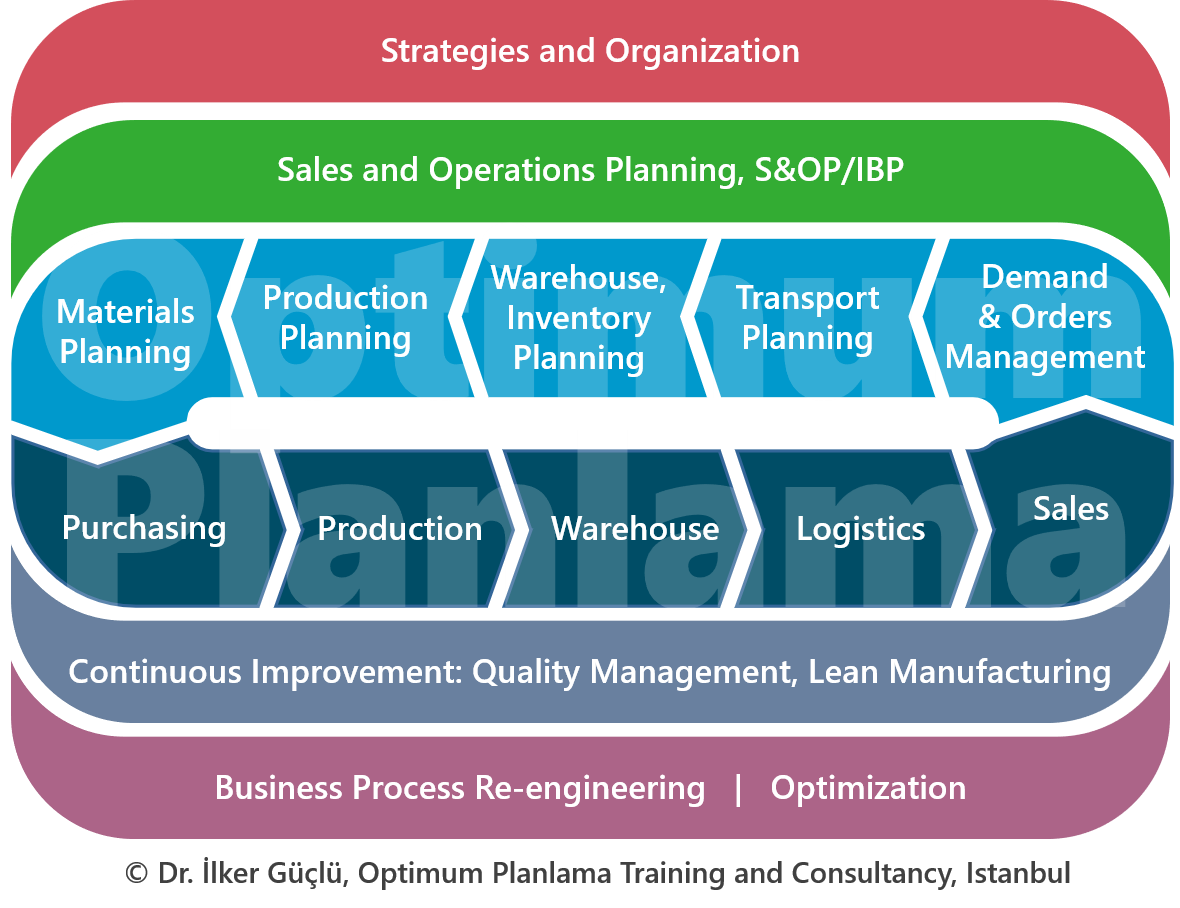

Where does Production Planning Sit within Supply Chain Management?

Supply Chain Management can be defined as the management approach that covers all stages from raw material sourcing through production, storage, distribution and delivery to the customer.

Production planning relates to functions such as sales, production, warehousing, logistics, purchasing and finance within supply chain operations.

Organizations aiming for excellence in supply chain management and production planning need to structure key functional planning processes.

Failure to integrate sales, production, purchasing, warehousing and logistics planning leads to inefficiencies and financial losses in resource usage and demand fulfillment, negatively affecting on-time delivery performance and profitability.

Therefore, production planning should not be treated in isolation; its relationships must be clearly defined within the organization.

Order Management, Sales and Demand Planning Relations:

Large deviations in demand forecasts, frequent order changes, cancellations, urgent orders, and highly urgent orders adversely affect purchasing, production, warehousing and logistics processes.

Effective coordination between demand planning and production planning is necessary to ensure customer satisfaction and proper use of resources and materials.

To learn more about demand planning, click here.

Purchasing and Inventory Relations:

Production cannot be considered independently of inventories. Raw materials and components must be procured so as not to disrupt production plans. In make-to-stock environments, inventory should be planned to protect against demand and supply fluctuations.

To learn more on inventory management, click here.

Warehouse and Logistics Relations:

Critical warehouse factors include receival, storage, order picking and loading/unloading capacities, as well as carrying and storage costs. Logistics planning organizes distribution of stocks to required locations, focusing on timing, modes of transport and routing. Warehouse and logistics constraints directly affect production plans.

To learn more on logistics planning, click here.

The related processes and general material and information flows are summarized below.

To learn more on supply chain management, click here.

What are Innovative Approaches and Trends in Production Planning?

Advances in information technologies have increased the adoption of innovative methodologies in production planning.

These approaches use various optimization techniques developed within the field of Operations Research.

Manual trial-and-error planning for complex production planning problems can be time-consuming, and may lead to suboptimal results. Innovative methodologies can generate more effective and reliable plans in much shorter timeframes.

These techniques help create plans that satisfy customers, increase resource efficiency and minimize costs.

To learn more on Optimization, click here.

Organizations should first identify gaps and needs in their current production planning processes, then design how to improve or re-engineer them.

What Optimum Planlama offers for Production Planning?

Optimum Planlama provides hands-on training and consulting services for production planning processes and identifying tools/software based automation needs.

We recommend in-house workshops for multi-site or complex manufacturers.

Our services for production planning and related processes are listed below.

To arrange an in-house training for your organization or to join a public session, request our proposal.