|

Training

Modules

|

Day

1:

Master Scheduling

and Order Management |

Day 2:

Materials and Capacity

Planning

|

|

Competition and Profit

Focus in Planning

Long and Medium Term

Production Planning

Demand Planning and Order

Management

Master Production

Scheduling, MPS

Backlog and Overloaded

Plans

When to Update & NOT to update the

Master Schedule?

In-Class Exercises

Available/Capable to

Promise, ATP/CTP

Flowshop / Jobshop,

Make-to-Stock /

Make-to-Order

Capacity and Bottlenecks

Management, RCCP

Material Planning: MRP

or Kanban?

Performance Indicators

in Production Planning

How to Optimize

Production Planning

Decisions?

In-Class Exercises

|

Material Requirements

Planning, MRP

Bill of Materials, MRP

Explosion, Time

Offsetting

Material Planning in

Make-to-Order

Co-Products,

By-Products, Recovered

Materials

Order Quantities in

Purchasing/Production

Capacity Requirements

Planning, CRP

In-Class Exercises

Capacity Planning by

Production Environment

Theory of Constraints,

TOC, Bottleneck Planning

Lean Manufacturing,

Wastes, Line Balancing

Technologies Selection:

ERP, APS

Performance Indicators

in Material Planning

How to Optimize Material

Planning Decisions?

In-Class Exercises

|

|

Day

3:

Detailed Scheduling

of Work Flows |

Day 4:

Detailed Scheduling

with Advanced Algorithms

|

|

Production Activities

Control, PAC

Cycle Times, Queues,

Setups

Finite-Infinite,

Forward-Backward

Scheduling

Basic Concepts of Detail

Scheduling

Resources, Operational

Constraints, Objectives

Detail Scheduling with

Gantt Charts

In-Class Exercises with

Gantt Charts

Dispatching

Rules in Operation

Sequencing

Decreasing Queues,

Work-In-Process

Inventory

Scheduling with Material

Supply Restrictions

Preventing or Reducing

Delays

How to Minimize Setup

Losses?

Effects of Process

Quality and Lean

Manufacturing

In-Class Exercises with

Gantt Charts

|

Scheduling in Resources

with Similar

Capabilities

Detailed Scheduling of

Flowshop Production

Production Lot Sizes and

Transfer Lots

Detail Scheduling of

Jobshop Production

Alternative Approaches

and Algorithms

Exceptions and

Optimization

In-Class Exercises with

Gantt Charts

How to Determine

Reliable Duedates?

Project Scheduling in

Production, CPM

Optimization with

Heuristic Algorithms

Optimization with

Mathematical Modeling

Optimization with Mixed

Methods

Automation in Detailed

Scheduling

In-Class Exercises

|

|

Executive

Reviews

Full- or

half-day sessions

for focused on critical

issues and decisions at

the executive level.

Contact us for more

information.

|

|

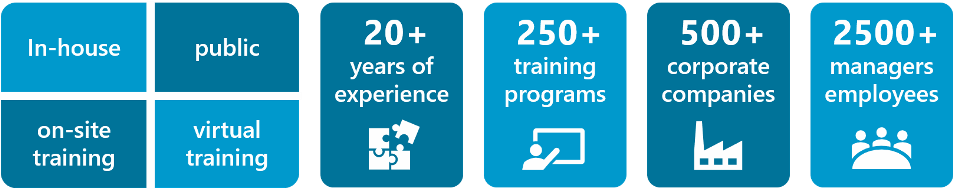

In-House

Sessions

|

Şişecam,

2011-2016 |

Akkök Holding,

2012 |

Keten Textile, 2013 |

Fil Filter,

2013 |

BTA Catering,

2013 |

|

Hisarlar Machinery,

2013 |

Kardem Textile,

2014 |

Gates,

2014 |

Kaleseramik, 2014 |

TAI-TUSAŞ,

2015,

2018 |

|

Vitra & Artema,

2016 |

Başoğlu Cable,

2016 |

Kastamonu,

2017 |

CMS,

2017 |

ZF Lemförder,

2017 |

|

Tempa

Pano, 2017 |

Jantsa, 2018 |

TEI-TUSAŞ, 2019 |

TPI Composites,

2019 |

LAV-Gürallar,

2020 |

|

TÜBİTAK BİLGEM,

2021 |

Alcam,

2021 |

Eczacıbaşı Esan,

2021 |

Panasonic,

2023 |

|

Contact

us for closed

session training

requests for

your team.

Testimonials

- This

part is

under

construction,

but you

can

always

use

Google

Translate

|

"Genel üretim planlama uygulamalarında büyük resmi görmek ve aynı zamanda detaydaki uygulamalar hakkında bilgi sahibi olmak isteyenler için güzel bir eğitim programı..."

Oryal Etiler, Üretim Planlama Müdürü, ŞİŞECAM (CAM AMBALAJ) |

|

|

"Üretim

planlama ile

uğraşan ya da

ilgi duyan

herkesin

kesinlikle

olması gereken

bir eğitim.

Planlama ya

farklı

pencerelerden

bakmanızı

sağlıyor. Meslek

hayatında ve

kariyer

gelişimimde bir

çok yeni

fikirler

edinmemi

sağladı. Üretim

planlama

yaparken aldığım

eğitim ile daha

iyi analizler

yapıp daha

optimum ya da

Optimuma yakın

sonuçlar

bulacağımı

inanıyorum..."

Emin Bahar,

Üretim Planlama

Takım Lideri,

TEI - TUSAŞ |

|

|

"Teorik bilgilerden bağımsız olarak yaptığınız işin, doğru yanlarını görmekle beraber hangi noktalarda eksiklerin ve geliştirilmeye açık yönlerin olduğunun farkına varmanızı sağlayan etkili bir eğitim olduğunu söyleyebilirim. Her mevkide, tüm üretim ve hammadde planlama ile satış/pazarlama çalışanlarının katılmasını tavsiye ederim. Ertesi gün kesinlikle yapılabilecek bir şeyler çıkacak..."

Burak Erkun, Üretim Planlama Müdürü, PENTİ |

|

|

"Planlama, tüm üretim sürecinin gidişatının belirlendiği bir iştir. Bu işi hem uzun vade hem de kısa vade bakarak yapmak gerekiyorki riskleri önceden görüp aksiyon alalım ve üretime en verimli hali ile yansıtalım. Bu eğitim bize uzun vadeden başlayarak en kısa vadeye kadar bu işin sistematiğine öğretti. Bizim dinamiklerimizi dikkate alarak bu sistematiği nasıl şirkete yansıtacağımızı tartışarak da bize uygulama yolunu gösterdi. Anlaşılırlık, açıklık ve örnekler ile yapılan bu eğitimin çok yararlı olacağı kanaatindeyim..."

Deniz Yalçın, PKW Üretim Müdürü, ZF LEMFÖRDER |

|

|

"Katılımcının öğrenme hızına/şekline uygun, özenle tasarlanmış bir eğitim... Teşekkürler..."

Volkan Cılga, Genel Müdür, CAKES & BAKES (TAV HOLDING) |

|

|

"Rekabetin arttığı

günümüz şartlarında iyi

planlama yapabilmenin de

önemi giderek

artmaktadır. Bunun en

büyük etkilerini

zamanında tedarik, doğru

terminlerine ve minimum

stok yönetimi vb.

konularda görmekteyiz.

Bu nedenledir ki bu

alandaki değişim ve

gelişimleri takip etmek,

iyi bir planlama

yapabilmek için mutlaka

gerekmektedir."

Aylin Erpak Kurtcu,

Üretim Planlama Müdürü,

ABDİ İBRAHİM

İLAÇ |

|

|

"Üretim planları yapmak ve çizelge oluşturmak, bir çok kısıtı ve farklı amaçları göz önünde bulundurmasından dolayı oldukça zor ve zaman harcamanız gereken konular. Ortaya çıkan her yeni kısıt bu problemi daha da zorlaştırıyor. En az zamanda, tüm kısıtları dikkate alan, amaca uygun en iyi çizelgeleri ve planları oluşturmak; hangi noktada hangi yöntemleri kullanmanız gerektiğini bilmekle mümkündür. Almış olduğum bu çizelgeleme eğitiminin farklı yöntemleri ortaya koyma ve farklı bakış açıları kazandırmada çok faydalı olduğunu söyleyebilirim."

Hürdoğan Güneş, Üretim Planlama Mühendisi, BRİSA |

|

|

"Artan

rekabet

koşullarında

kısıtlı

kaynakların

doğru

kullanılmasının

ve

yönetilmesinin

önemini ortaya

koyan çok önemli

bir eğitim..."

Ersen Gazel, Planlama

Müdürü,

SAMET

KALIP |

|

|

"Üretim Planlama ve

Çizelgeleme ile ilgili

olarak tüm teorik

bilgilerin baştan sona

anlatıldığı ve bu

noktalar içerisinde

kendi sürecimizde önemli

olan noktaların

farkındalığını artıran

bir eğitim oldu. Bu

anlamda kritik noktalara

eğilip süreçlerimizi

daha iyi seviyeye

getirmek için yol açmış

oldu."

Arif Cez, Tedarik

Zinciri Müdürü,

İPEK KAĞIT |

|

|

"Üretim planlama

konusunda klasik

ve yenilikçi

yaklaşımları

özetleyen,

anlatımı

örneklemelerle

destekleyen

güzel bir

eğitim. Kurumsal

planlama

sürecimizi

iyileştirmemizde

yol gösterici

olacağına

inanıyorum..."

Serdar Soyöz, Operasyon

Müdürü ,

GATES POWERTRAIN |

|

|

Eğitim öncesinde bu kadar tatminkar bir eğitim alacağımızı düşünmemiştim; çizelgeleme ile ilgili tüm unsurların yerli yerinde anlatıldığı bu eğitim özellikle Detay Çizelgeleme sürecini gözden geçirmek isteyen kurumların planlamacılarına ve belirlenmiş ise Bilgi Teknolojisi proje ekibine mutlaka sağlanmalı ve bu sayede gelişim projelerini daha sağlıklı ele alacakları bir ortam oluşturulmalı kanaatindeyim

Mustafa Altan, Üretim Planlama ve Kontrol Müdürü, ECZACIBAŞI ARTEMA |

|

|

"Detay Çizelgeleme eğitimi ile birlikte süreçlerimizin içerisinde geliştirme fırsatları olduğunu fark ettik. Bu eğitim daha fazla ne yapılabilir sorularını karşılayacaktır. Çizelgelemede, firmaların uyguladığı deneme-yanılma metotlarının sezgisel algoritmalar sayesinde bir zemine oturtulması şansı olduğunu gördük..."

Barış Çelik, Tedarik Zinciri Planlama Müdürü,

KASTAMONU ENTEGRE |

|

|

Gelecek vizyonu

açısından alınması

gereken bir eğitim

olduğunu düşünüyorum.

Eğer rekabetin bu kadar

acımasız olduğu bir

piyasada var olmak

istiyorsak özellikle

Satış ve Operasyon

Planlama konusunda tüm

şirketlerin eğitim

alması gerektiğine

inanıyorum

Mustafa Aydın, Planlama ve

Lojistik Grup

Müdürü, HASÇELİK |

|

|

"Eğitimden sonra

işletmemizde detay

çizelgeleme

uygulamalarına başladık.

Bu programı daha etkin

bir planlama yapma

hedefi olan tüm

işletmelere öneriyorum."

Özer Özgür Yılmaz,

Üretim ve Planlama

Müdürü, BOSCH REXROTH |

|

|

Planlama süreçlerini

genel hatlarıyla

inceleyerek hangi konuda

ihtiyaçlarınız olduğunu

anlayabilmeni için bu

eğitime katılmanız

önemlidir. İnteraktif

bir eğitim olması

sebebiyle sürecinizdeki

sıkıntıları tartışarak

bir sonuca

ulaşabilirsiniz. Faydalı

bir eğitim olduğunu

düşünüyorum...

Latif Mutlu

Şahan, Fabrika

Direktörü, HİSARLAR

MAKİNA |

|

|

"Günümüz rekabet

koşulları göz

önüne

alındığında

kalite,

karlılık,

verimlilik

şartlarının

sağlanması

açısından

planlama olmazsa

olmazların

içerisindedir.

Bu bağlamda

kurumların genel

planlama

süreçlerini

anlayıp hayata

geçirebilmeleri

adına çok

yararlı bir

eğitimdir..."

Erkan Yüksel, Planlama

Müdürü,

BAŞOĞLU KABLO |

|

|

"Üretim planlama ile

ilgili daha önce de

eğitim programlarına

katıldım. Planlama ile

ilgili problemlerime

işyerinde uygulamaya

dönük faydası olmadı. Bu

eğitimde aldığım

bilgilerin pratikte

uygulanabileceğine,

bundan sonraki planlama

işimde kolaylıklar

getireceğine

inanıyorum."

Hakan

Gök, Üretim Planlama & Satın Alma

Müdürü, ESAN AKÜ |

|

|

"Planlama ve

çizelgeleme

konusunda,

yenilikçi

fikirler ve

örneklemeler ile

genel manada

doyurucu bir

eğitim oldu.

Teşekkür ederim.

Bu bilgiler

ışığında

mevcutta

uyguladığımız

planlama

bilgilerine,

yeni bilgiler

ile hem

firmamıza hem de

ülkemize destek

katacağımızı

düşünüyorum."

Erol Okçu,

Planlama &

Hammadde Depo

Müdürü, KİLİM

MOBİLYA |

|

|

"Eğitimin verdiklerinin

çok yönlü olduğunu

düşünüyorum, klasik

bilinenlerin her kuruma,

her ürüne ve her duruma

uygun olduğunu

varsaymadan her sürecin

nedeninin ve niçininin

sorgulanması

gerektiğini; bazen en

olumlu dediğinizin bile

üstünde bir çözüm

olabileceğini gösteren

bir eğitimdi.

Teşekkürler..."

Mine Okumuş,

Satın Alma & Planlama

Müdürü, EMİNİŞ AMBALAJ |

|

|

"Planlamanın her

kademesindeki

çalışana değer

katacak, farklı

bir bakış

açısına sahip

olmasını

sağlayacak bir

eğitim..."

Gamze Çakır,

Üretim Planlama

Koordinatörü, OPET FUCHS |

|

|

"Planlama yaparken

karşılaştığımız

sorunlara genel çözümler

getirmek, boğulduğumuz

detayları tümden görüp

önlem almak ve planlama

kriterlerimizi

geliştirip firmanızı

daha kaliteli ve

ekonomik sonuçlara

ulaştırmak için

kesinlikle alınması

gereken bir eğitim..."

Onur Akyürek, Üretim ve Planlama Müdürü, UKINOX ANKASTRE |

|

Photos

|

|

Click for

photos

from past

events. |

Instructor

|

|

Training

modules

will be

presented

by Dr.

Ilker

Guclu,

the

designer

and

developer

of the

program.

Dr.

Guclu

has

completed

his

undergraduate,

graduate

and

doctorate

studies

in

Istanbul,

at

Bosphorus

University,

Department

of

Industrial

Engineering.

Since

2003, he

has been

carrying

out

training

and

consultancy

activities,

with the

last 15

years

focused

on

management

and

optimization

in

supply

chains.

Dr.

Guclu is

married

and has

two

children.

Click

for his

curriculum

vitae.

Follow

on

LinkedIn

|

|

Our Education and Learning Approach

|

|

|

|

|

|

|

|

Focused

training

modules |

Custom

configuration |

Flexible

dates

and time |

Effective

and

efficient

sessions |

Certification

and

Exams

|

Certification

Participants

will receive a

Certificate

of Participation

for each of

the modules that

they attend.

Participants

attending all

the modules will

be qualifed to

take the

certification

examination.

Participants

that succeed in

the examination

will receive the

following

certificates in

addition to the

Certificate of

Participation.

- 60% or

higher of

total points

will receive a

Certificate

of

Accomplishment

approved by

Optimum

Planlama.

- 90% or

higher of

total points

will receive a

Certificate

of Outstanding

Accomplishment

approved by

Optimum Planlama

.

There will be

retests for

those who cannot

fulfill the

accomplishment

criteria.

Retests are

subject to

additional fees.

Closest

Dates

and

Locations

Sessions during

the day are

between 9:00 and

16:00, including

coffee breaks

and the lunch

break.

Number of

participants

will be

limited to enhance the

learning

experience.

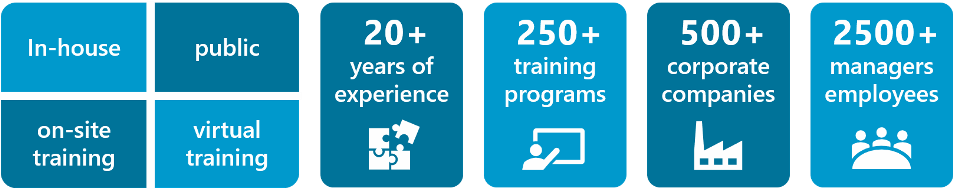

Experience

and

References

Click

for complete list of our

References.

Pricing

and

Registration

We will gladly

fulfill your

in-house or

public training requests.

▲

TOP OF PAGE |